| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | BT |

| Model Number : | BT-2113B |

| Certification : | ISO9001/CE |

| Price : | USD350000 |

| Payment Terms : | T/T |

| Supply Ability : | one set per 90 days |

| Delivery Time : | 90 work days |

Fully-automatic battery pack assembly line

Scope of equipment

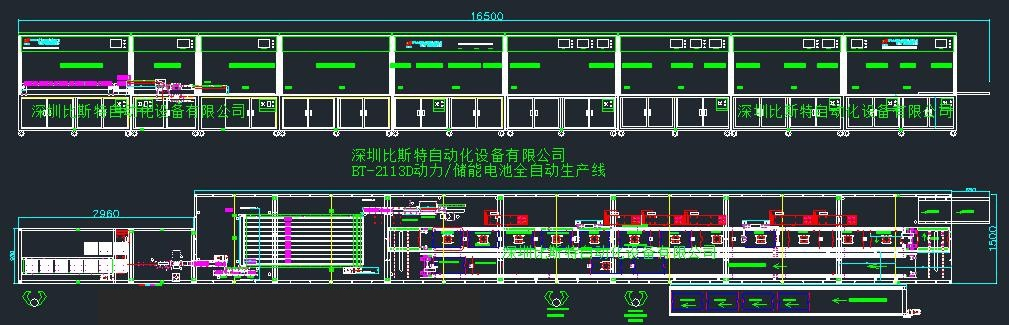

BT - 2113B Automatic Lithium Ion Battery Pack Production Line 18650 / 21700 / 32650 Cylindrical Energy Storage / Power mainly used in automotive battery modules. Fully automated production of power batteries, energy storage batteries, power tool battery packs and other application batteries.

Features

1.Customized for 18650/21700/26650/32650 type of cells.

2. Only three operators are needed from boxed cell to welded battery pack.

3. Optional cell scanning function, set cell data into the bracket or combination of batteries, the battery data can be tracked.

4. Using 4 axis Yamaha robot automatically into the bracket, stable and reliable performance.

5. Adopt Hikvision series CCD cell positive and negative polarity identification to ensure that there is no polarity error phenomenon when the cell enters the bracket.

6.Production efficiency: 5000-6000pcs /H

Working process

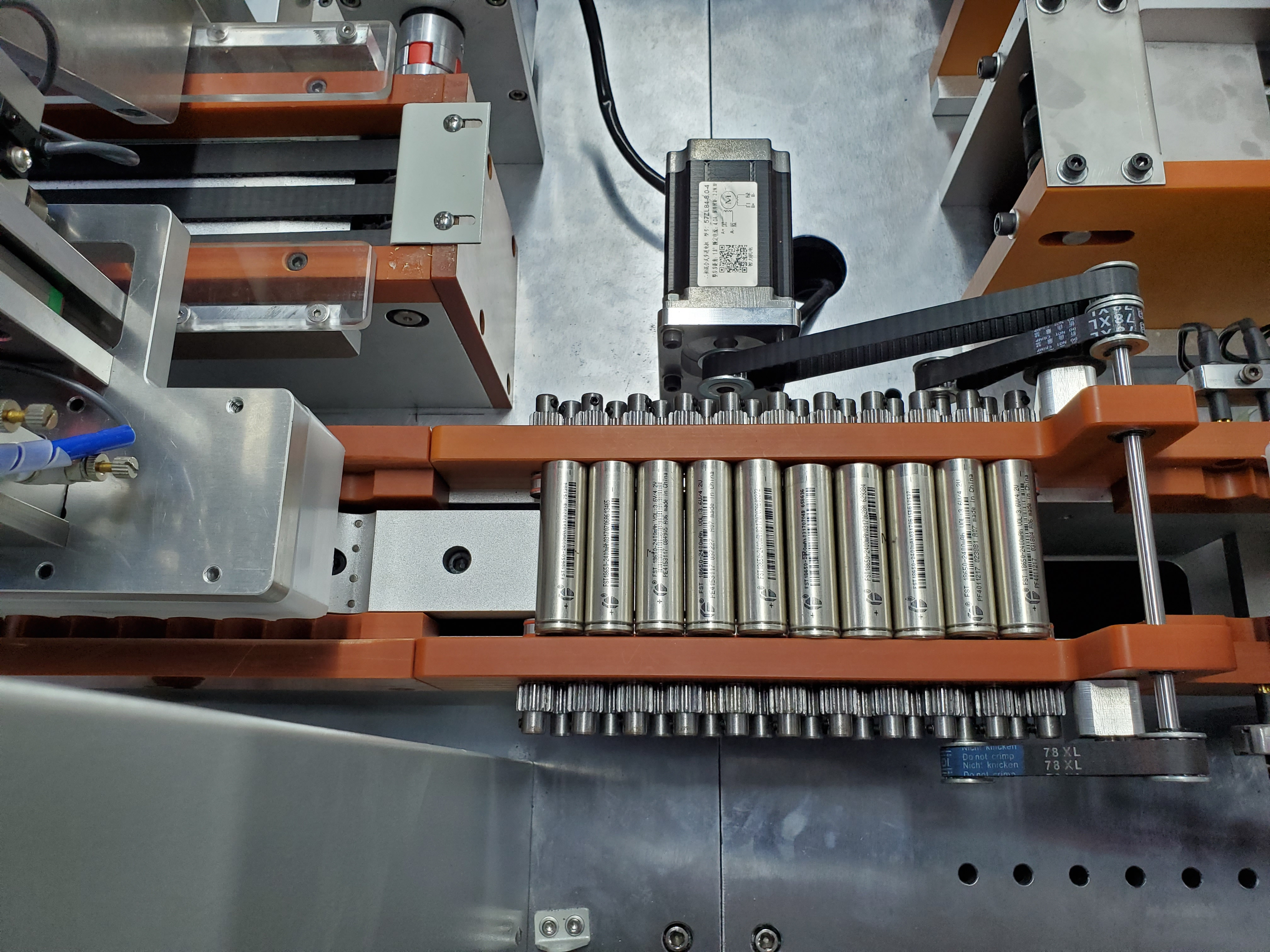

Automatic boxed cell (10*10) automatic feeding → automatic insulation paper pasting → automatic code scanning → automatic sorting (10 grade OK, One NG) → automatic cell sorting → automatic scanning code → robot into the bracket →CCD vision positive and negative detection → laser cleaning A → mold flip 1→A spot welding 1→A spot welding 2→ mold flip 2→B spot welding 2→B spot welding 2→ automatic Take out the top cover → automatically take out the battery → assembly line of semi-finished battery products (spot welding appearance inspection → attaching auxiliary materials → protection plate connection → shaping → comprehensive performance test and other stations)

Technical parameters

BT - 2113B Automatic Lithium Ion Battery Pack Production Line 18650 / 21700 / 32650 Cylindrical Energy Storage / Power

| Automatic cell feeding |

| Power supply: AC220V±10% 1KW 50HZ±10% Air source: 0.4-0.8mpa, no water mist, no impurities The box cell is packed in 10*10 cartons, with a maximum of 5 boxes at a time The box cell is packed in 12*15 cartons, with a maximum of 4 boxes at a time Adopt Taiwan upper silver guide rail Cell shift power: stepper motor/decelerator motor Control system: XC2-24T-E PLC programmer Operation interface: TG-765-UT color display screen, easy to operate Cylinder: Attec /SMC/XINCHENG Pneumatic control components: ATech /SMC/ Tiangong/Pneumatic Like Induction device: Taiwan LIKE/ Adeke // Omron/Keenshi Production efficiency: more than 4500PCS/H Main FUNCTIONS: MANUALLY PUT the cell in the box into the box assembly line, automatically enter the position of the cell, and push the empty box into the storage box.The cells in the cartons are automatically removed and transferred to the line of the automatic surface cushion machine, which is compatible with different diameter of 21/18 electric cell packaging boxes |

| Automatic insulation paper pasting |

| Power supply: AC220V±10% 1.6KW 50HZ±10% Air source: 0.4-0.8mpa, no water mist, no impurities Adopt 4 - pin cushion mechanism to improve efficiency Adopt frequency conversion motor and CAM punching pad to prevent battery damage Japanese high speed steel die, design life of 5 years Automatic rewinding of waste materials Adopt Taiwan silver guide rail, lead rod The lower cell motor adopts Taiwan force reduction motor Power of manipulator: closed-loop stepper motor/servo motor Cell shift power: stepper motor Control system: XD-42T-E PLC programmer Operation interface: TG-765-UT color display screen, easy to operate Built-in fault alarm system (according to the prompt to remove the fault) Automatic alarm for shortage of highland barley paper Quantitative reminder of die cleaning Cylinder: Attec /SMC/XINCHENG Pneumatic control components: ATech /SMC/ Tiangong/Pneumatic Like Induction device: Taiwan LIKE/ Adeke // Omron/Keenshi |

| IR tester |

| Test power: Star pneumatic Cylinder: Attec /SMC/XINCHENG Pneumatic control components: ATech /SMC/ Tiangong/Pneumatic Like Induction device: Taiwan LIKE/ Adeke // Omron/Keenshi Test efficiency: above 4500PCS/H Test needle model: KS-100A3000 Test needle life: 600,000 times Main functions: single test cell voltage and internal resistance, through the servo motor shift, test 10 cells, from the cell shift mechanism to triple shift mechanism 1, test data in the sweep code completed and cell bar code binding, storage database Tester model: HIOKI BT3562 optional domestic HK3560 Test channel: channel 1 Voltage reading accuracy: plus or minus 0.02MV Internal resistance reading accuracy: plus or minus 0.2 Hao Repeated tests are consistent Test data in the sweep code completed and cell bar code binding, stored in the database Test efficiency: 5000PCS/H |

| Automatic scanning |  | Honeywell/Genz/HiKVision sweep code Custom light source is used to ensure the accuracy of code reading Identification system: Bicester independent research and development Camera width: within 300*150MM Executive device: Industrial computer, genuine WIN7 system Main Functions: Sanlian shift 1, sweeps the batteries into the code, start the step motor drive gear, the batteries clockwise, to read bar code data binding, not read bar code and test negative sentences is bad, the test data in the code completion and batteries barcode binding, store database, MES system docking with party a, don't sweep yards, and yards function can be blocked, 11 sets of gear transmission, with rubber ring to increase the friction on the core, to ensure the normal rotation of the core, normal reading, 18650 and 21700 cells universal Scanning efficiency: more than 3500PCS /H |

| Automatic sorting |

| Adopt Taiwan silver guide rail, lead rod Automatic gear manipulator power: 2 axis 400W servo motor Module: 2 axes It is stable and reliable to grab 10PCS of electric cell at one time and adopt cylinder telescopic permanent magnet Control system: XD series PLC programmer Sensor: Taiwan LIKE/ Actek /SMC/ Phenom/Airtek Operation interface: TG-765-UT color display screen, easy to operate Main FUNCTIONS: ACCORDING to the range of set voltage internal resistance, put the cell into the corresponding pipeline slot, 18650 and 21700 cells are universal Use 3 synchronous belt transmission Transmission power: 25W reducer motor Sensor: Taiwan LIKE/ Actek /SMC/ Phenom/Airtek Number of stalls: 5 OK stalls The assembly line is divided into cell feed and cell discharge The discharging level of the cell is equipped with automatic mounting mechanism, which opens automatically when the cell is taken 18650 and 21700 cells are universal |

| Lifting cell storage mechanism |

| Power supply: AC220V±10% 1.6KW 50HZ±10% Adopt Taiwan silver guide rail, lead rod Lift power: Brake reducer motor Storage capacity: 18650 about 240PCS, 21700 about 180PCS Lifting speed: 8MM/ SEC Control system: XD series PLC programmer Sensor: Taiwan LIKE/ Actek /SMC/ Phenom/Airtek Operation interface: TG-765-UT color display screen, easy to operate 18650 and 21700 cells are universal |

| YK400XR Yamaha robot |

| Robot model: Yamaha YK400XR Valid range: radius 360MM Load weight: 3KG Main functions: The robot takes out the well-spaced electric cell and inserts it into the bracket (or without bracket mold). Efficiency: 5000-6000 PCS/H Technical parameters: See Yamaha manual for details Main functions: Special research and development of control system for Yamaha robot Manually set robot coordinates and actions Match Yamaha 4-axis / 6-axis robot Debugging is simple, easy to learn, easy to understand The 7.5-inch touch screen displays the current status Operating system: Bicester independent research and development |

| CCD tester |  | Power supply: AC220V±10% 0.6KW 50HZ±10% Hikvision 10 million HD camera Identification system: Bicester independent research and development Camera width: 420*300MM or less Executive device: Industrial computer, genuine WIN7 system Main functions: CHECK and compare the positive and negative electrodes of the plugged cell, and stop the operation if the position is wrong or the polarity is back, waiting for manual confirmation before release Scanning efficiency: more than 6000PCS cell /H During normal production, every test, when qualified, the screenshots will be sent to the MES system of your company for preservation (about 8M each). Interface mode: Webserive Send Send: Send in hexadecimal format |

| A surface welding |  | Main function: Automatic spot welding for single side of battery pack Standard HEQUAN(Bicast), MDA8000B/MDB4000B transistor welding power supply, Optional MIYACHI MDA8000B/MDB4000B transistor spot welding power supply With current detection function, false welding, explosion fire alarm Four-axis pure servo motor operation Spot welding coordinate data can be imported by U disk or array Positive and negative welding currents can be set differently (spot welding specification) Single cell can be set at a certain position without spot welding Spot welding needle cooling: standard with chiller Standard rotating welding head, plus or minus 90 degrees rotation (plus or minus 90 degrees range, arbitrary setting) Optional automatic grinding welding needle function Optional welding needle pressure detection function Welding data acquisition and upload Interface mode: Webserive Send: to be sent as a string in XML format Spot welding efficiency: more than 4500PCS cell /H (calculated according to the two times of spot, 4 welding spots for the positive electrode and 4 welding spots for the negative electrode) Spot welding of nickel :0.08-0.15 nickel plating or pure nickel without the diversion groove welding 0.15-0.2 nickel plating or pure nickel is recommended to be welded with a diversion groove Convex welding is recommended for nickel plating above 0.2mm -0.5 or pure nickel |

| Mould flip |  | Main function: Turn the mold into B side automatic spot welding Turnover efficiency: 20S/ time |

| B surface welding |  | Same as A surface Could be customized for single side weldiing or two sides |

| Battery fetching manipulator |  | Main Functions: Remove the spot-welded battery and transfer it to the circulation line or assembly line Efficiency: 20S/ time |

FAQ

A:How do I confirm that you are the manufacturer?

B:1)Clear front desk photo with our factory name.

2)Video calls during working hours, no advance booking is required.

3)Any time agent visit factory,no advance booking is required.

4)Inquire production progress at any time, provide photos and videos, etc.

5)Professional engineers solving after sale service problems.

A:What types of machines can we make?

B:All kinds of battery assembly machines.Cell testing,insulation paper sticking,sorting,welding,testing,aging.

For cylindrical/prismatic/polymer cells,manual and automatic,single machine and production line.

A:Can you help me to set up a plant?

B:Yes,please provide your raw materials and products details,your requirements about efficiency,your budget,we will send a plan to you.If you need we can also introduce some suppliers of raw materials to you.

A:Do you support after sales service?

B:Yes, after purchase BT - 2113B Automatic Lithium Ion Battery Pack Production Line 18650 / 21700 / 32650 Cylindrical Energy Storage / Power we will have professionals to install and train, and the warranty is two years. Exported to Europe and the United States, Southeast Asian countries, there is a site in India

A:How can we solve machine problems?

B: Factory advantages,we have engineers and we produce the machines.

1)We will arrange an engineer to communicate with you when we get your message.He will guide you to solve the problem by video call or messages.

2)If the problem was caused by component damage,we will send a new component to you.After you get it,we’ll guide you on the video call about how to install it.

|